Product detailed description

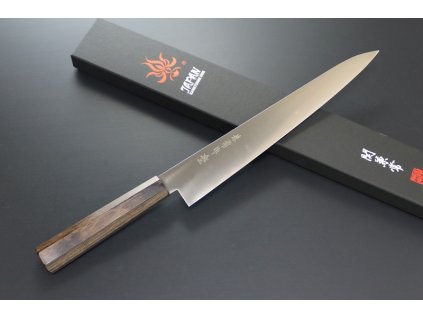

This XinCraft XC139 knife represents a technological advancement combining the traditional San Mai forging process with modern high quality materials. The core of the blade is made of 440C steel, which thanks to vacuum heat treatment achieves high hardness (HRC 59±1) and excellent sharpness retention. The blade surface layer of 410 stainless steel ensures excellent corrosion resistance. The blade finish consists of acid etching, which gives the knife a unique appearance and protects the surface from environmental influences.

The handle of the knife is made of stabilized maple with a distinctive texture that not only provides resistance to moisture and warping, but also provides a unique aesthetic appearance. There is a brass spacer ring insert between the handle and the blade, which adds to the strength of the construction and aesthetic appeal. The knife is designed in a full tang construction, which means the blade runs the full length of the handle, providing maximum stability and balance when working.

Knife type: chef's kitchen knife, 20 cm

Blade material: 440C steel core with 410 stainless steel surface (San Mai forging)

Overall length: 320 mm

Blade length: 205 mm

Blade thickness: 4.5 mm

Core hardness: HRC 59±1

Handle material: Stabilized spalted maple burl

Handle length: 115 mm

Net weight: 183 g

Origin: Handmade in China

Usage Instructions:

Use the knife for food preparation only.

It is designed for cutting fruits, vegetables, fish and boneless meat.

Only cut on blade-friendly surfaces such as wood, plastic or rubber.

Wash by hand with mild detergent, rinse and dry thoroughly. Do not use a dishwasher.

Store knife in a block, protective sheath or padded box to minimize risk of damage.

Podobné produkty

Code: SM0010

Code: SM0010

Code: KC-313

Code: KC-313

Code: 2C 759/18

Code: 2C 759/18

Code: 2C 1020 NO

Code: 2C 1020 NO

Code: KC-861

Code: KC-861

Code: KC-866

Code: KC-866

Be the first who will post an article to this item!

XIN Cutlery products represent a symbiosis of modern technology and progressive design. Each knife is created with an emphasis on optimal blade geometry to maximize cutting performance and long-term blade durability. Material selection relies on advanced alloys and powder metallurgy, with blades using high carbon and chrome steels for a combination of toughness and extreme wear resistance. Damascus is also often used.

The blades are processed through a multi-stage heat treatment process involving cryogenic treatments and precise hardness calibration to values between 59-62 HRC, achieving an optimum balance between hardness and blade flexibility. The ergonomics of the handle reflect the needs of professional users and enthusiasts alike, with materials such as carbon fibre and G10 ensuring strength, light weight and a comfortable grip.

XIN Cutlery, as part of Bestech Knives, draws on a wealth of experience in premium knife manufacturing and pushes the boundaries of innovation towards the perfect balance between form and function. Sharpness is not the goal here, but only the beginning of the journey towards the perfect cutting tool.

Related products

Code: C5310

Code: C5310

Code: C5313

Code: C5313

Code: 2CB3010

Code: 2CB3010

Code: 2CB3012A

Code: 2CB3012A