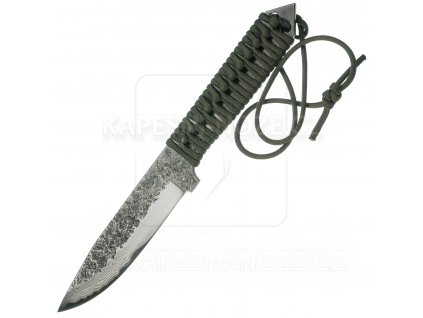

damašek

Damascus steel

The steel processed and forged in Damascus was a masterful example of the skill of the local blacksmiths and is still known today. These craftsmen, who were able to combine contrasting steels into shapes and decorative variations and different motifs, often enhanced the quality of the blades by forging. The workmanship and functionality of these blades were second to none. It is a non-homogeneous but more or less regular internal structure, with alternating layers of at least two different types of steel. Nowadays, damascus blades are available in simple carbon steel variants, stainless steel variants and stacked sandwich variants of the damascus design, i.e. layering. Typically, they are formed with a double material if some more distinctive pattern is desired, or perhaps even simple functionality where the cutting part is left harder and the sheathing made of e.g. stainless steel for greater corrosion resistance. These combinations and motifs are countless.

Stainless steel damascus

(e.g. damasteel made by uddeholm of Sweden, typically a combination of RWL34 and PCM17 = DS93x steels) and other stainless steel damasks are made of more advanced materials and are fully functional in terms of durability and blade life. Most of the time, we cannot find the exact composition of the steels used to make these stainless damasks, but they offer a full-featured yet ornamental blade, with material comparable to very high quality steels. Most of the time, it is really a prestigious affair.

Pakistan damascus

Rusting damascus made from materials that are not precisely specified, they have a high contrast pattern but inconsistent characteristics on the edge.They are highly decorative and sought after for their lower price and interesting concept and workmanship.

Sandwich damascus / San-Mai

In this type of damascus, the overlaid steel is of a double type, the so-called functional damascus - clad, Japanese damascus, where the inner part, the cutting part, is of a harder material and is surrounded by a softer material that gives some surrounding protection to the fragile blade, it can be layered for higher contrast of layers, it is then more decorative. The highest quality functional solution. The inner steel tends to be carbon but this is not the rule, the surrounding layering is then typically stainless.