Knife steels and their complete detailed overview

GRADES of STEEL

and other materials for the manufacture of knife and blades

When searching for the desired steel, you can jump to the category (stainless, carbon), with a text description, or to the tables of chemical composition at the bottom of the page, or you can use the search function in the browser, |

||

with the help of keystroke

|

||

|

||

Beside the type of the steel is little hand  marking web-link, which will direct you to the knife category with the selected steel. marking web-link, which will direct you to the knife category with the selected steel. |

||

A simple grading of the best known steels can be found

|

||

jump to info about stainless steels and

jump to info about stainless steels and  table of chemical compositions

table of chemical compositions

jump to powder metallurgy stainless steel and

jump to powder metallurgy stainless steel and  table of chemical compositions

table of chemical compositions

jump to carbon tool steel and

jump to carbon tool steel and  table of chemical compositions

table of chemical compositions

jump to carbon steel and

jump to carbon steel and  table of chemical compositions

table of chemical compositions

jump to carbon steel made with powder metallurgy and

jump to carbon steel made with powder metallurgy and  table of chemical compositions

table of chemical compositions

jump to description of damascus steels

jump to description of damascus steels

STEEL

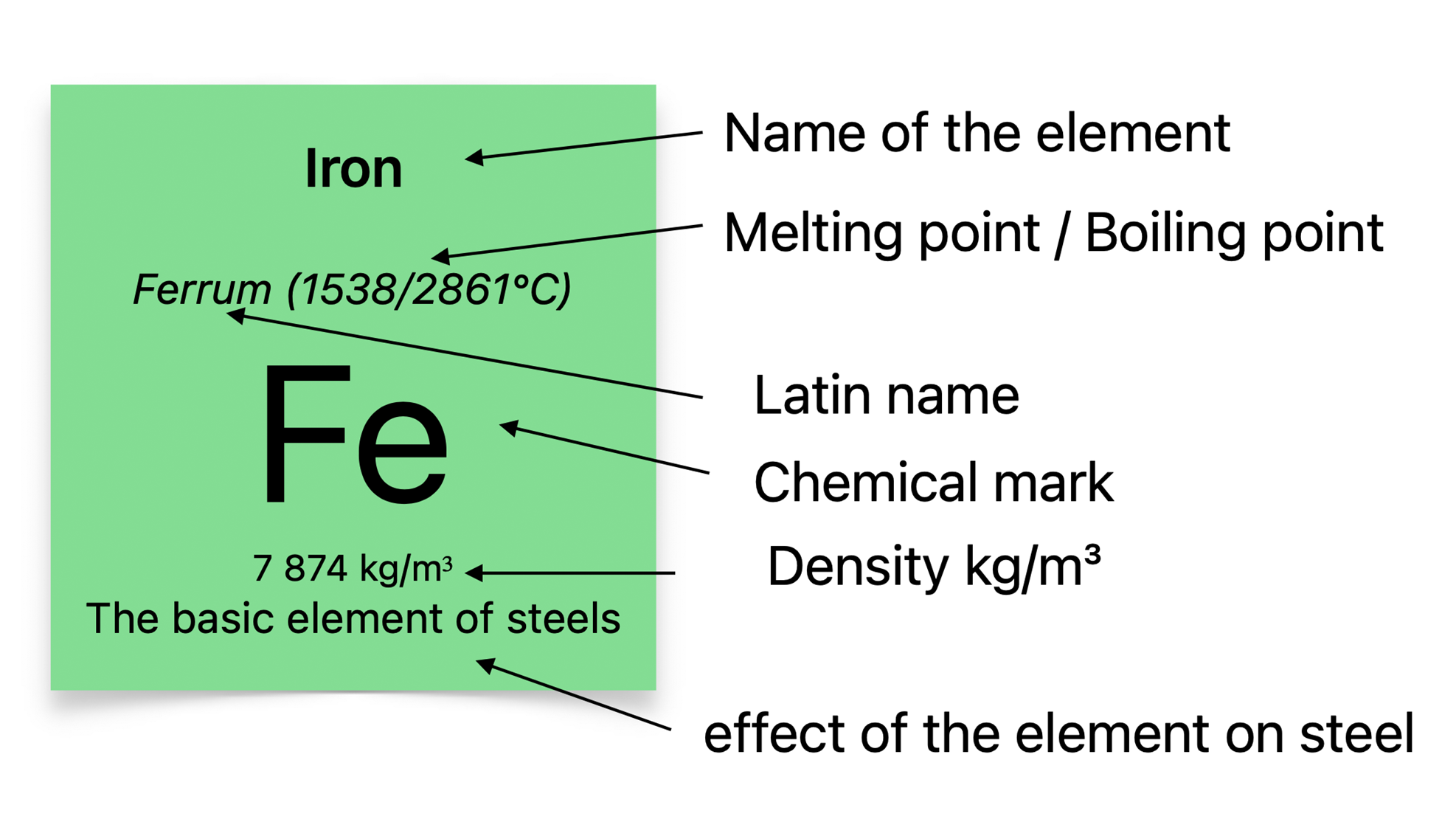

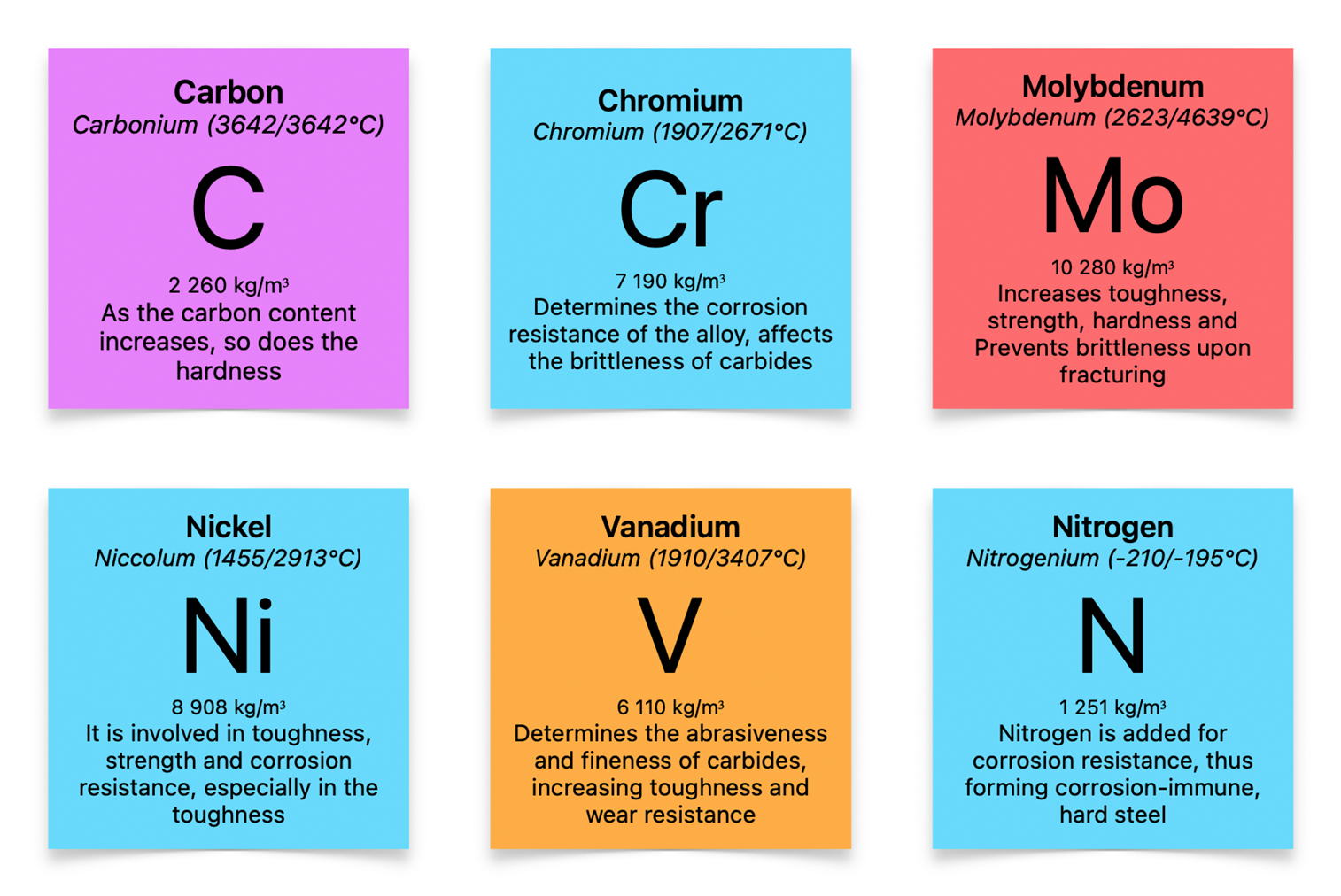

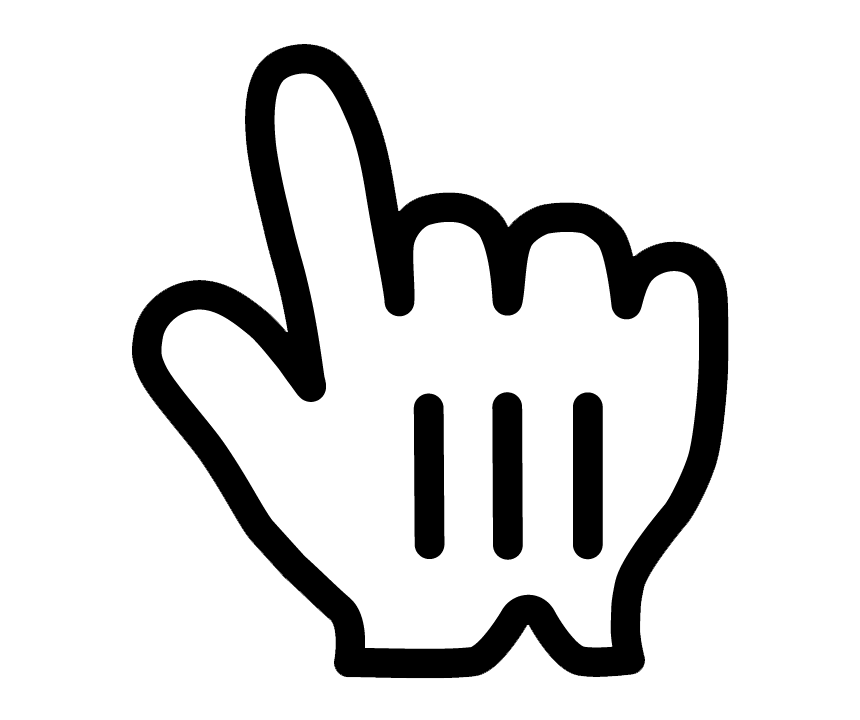

Steel, an alloy of elements, in particular, contains the element iron (Fe - ferrum) to the greatest extent, when other elements are added in certain proportions to give advanced properties to an otherwise rusting material. They refine it. If carbon is added to iron (up to 2.14%, as it would be cast iron at higher levels) or other elements, it becomes steel. Alloy steel, which by its properties can be hard, tough, corrosion resistant, resistant to wear, breakage and mechanical pressure, resilient to high temperature and so on.

The steels can then be low-alloyed (admixtures of elements other than carbon are below 5%), which can change mechanical properties by heat treatment; high-alloyed steels are then used with other elements to achieve the necessary mechanical, physical and chemical properties. The steel alloy can be rustless (highly resistant to corrosion) if we add enough Chromium (Cr) - typically we´re required to add more than 12%. • We may also add the exceptionally hard Tungsten (W), which makes the steel alloy significantly harder – in this case the downside is that the material becomes very hard to manipulate with in every way, especially the part when we sharpen the blade in domestic conditions. The conclusion is that we´re required to find some sort of suitable compromise, which is the part when we encounter an astonishing amount of different steel alloys, coming from a lot of different manufacturers, such as the Japanese Hitachi, the Austria's Uddelholm, the American Carpenter etc.

Quenching - i.e. hardening of steel is a process where we can change the crystalline structure of alloy steel by high temperature and this structure is as if locked by rapid cooling from very high temperature e.g. by oil, water, or air, or e.g. by liquid nitrogen to very deep sub-zero temperatures. This is to such an extent that the crystalline structure can be formed in various ways to improve the properties of the steel itself. However, the steel can also become very brittle after this procedure, and therefore a so-called tempering process is carried out, where the hardened steel is heated only to lower temperatures in order to loosen the carbides and the structure of the material and release the stresses. The steel then loses its hardness, but becomes tougher and more durable. These tempering processes can be several in turn, improving at least the structure of the steel according to the requirements of the material, to achieve the properties we desire.

The types of steel then basically differ into two main groups, stainless steel, which is basically more corrosion resistant. The second group is carbon steel, which has a much lower resistance but has a higher resistance to wear.

The different proportions of the alloying elements in the steel result in countless combinations and types of steels. A more or less summary table can be found at the end of this article.

Tungsten Carbide

Tungsten carbide is an incredibly hard substance that is widely used in all aspects of engineering. It consists of tungsten (W) and carbon (C). Any form of manipulation with this substance is extremely complicated, since it can only be manufactured with diamond or silicon carbide. Tungsten carbide is used by some manifacturers as an extremely hard blade, or as an edge of widia drills. This kind of equipment is unusually long lasting thanks to its extreme hardness, which is about 71 HRC on the Rockwell scale.

Titanium

Titanium cannot be hardened (i.e. by thermal shock and rapid cooling from high temperature to harden the internal crystalline structure to a stronger bond) to a high HRC, therefore the knives do not have a very good quality edge. However, they are very light, non-corrosive and non-magnetic.

Ceramics

A very hard to dull blade that is hard but brittle. Knifes that contain ceramic blades are quite hard to sharpen and are therefore rarely used.

STEEL SPECIFICATIONS AND GRADES

Alloying elements of steels and their properties

- a simple classification of the most familiar steels you will find here

here

- table of chemical composition of steels is at the end of the page

end of the page

1. Stainless steel

1.1 Corrosion-resistant steel

It can be very resistant to rust if a higher percentage (typically more than 12%) of Chromium (Cr) is added to the resulting mix, or for example Nitrogenium (N), where there is a high resistance to corrosion even when exposed to salt water. The corrosion resistance is then influenced by the elements acting on it, whether it is just air humidity or resistance to acids, etc.

what effect do have the chemical elements on the steel?

what effect do have the chemical elements on the steel?

| star rank | DIVISION OF STEEL GRADES |

|

✭✩✩✩✩ ✭✭✩✩✩ |

we do not offer steel of lower grades |

| ✭✭✭✩✩ | basic branded steel that offers quite decent performance for a lower price |

| ✭✭✭✭✩ | more advanced steel, which offers better properties than basic steel by a more balanced composition |

| ✭✭✭✭✭ | superior performance and exclusive properties of these steels |

| ✭✭✭✭✩ |

H1

|

|

| ✭✭✭✭✩ |

H2 (advanced H1)

|

|

| ✭✭✭✩✩ |

420 (AISI 420; X20Cr13; 1.4021; ČSN17022; SUS420J1)

|

|

420J2 (AISI 420M; 1.4028; SUS420J2; ČSN17023)(C) 0.26-0.36%, 12-14% (Cr), 1% (Mn), 1% (Ni), 1% (Si). It is a basic stainless steel, difficult to weld with a lower carbon content. With hardness of approx. up to 53 HRc (according to Rockwell). This steel is extremely resistant to rusting and to weaker chemical agents, very machinable, polishable but soft. It is very often used for making fantasy knives, swords, etc. It can be sharpened very easily in the field. Has slightly higher wear resistance than basic 420 steel |

||

| ✭✭✭✩✩ |

420HC High carbon (TruSharp steel)

|

|

| ✭✭✭✩✩ |

440A (AISI 440A; X65CrMo14; 1.4109)

|

|

| ✭✭✭✩✩ |

440B (AISI 440B; X90CrMoV18; 1.4112)

|

|

| ✭✭✭✩✩ |

440C (AISI 440C; N685; X105CrMo17; ČSN 17042; 1.4125)

|

|

| ✭✭✭✩✩ |

W.1.4034 (X46Cr13; N540; ČSN 17029)

|

|

| ✭✭✭✩✩ |

3Cr13

|

|

| ✭✭✭✩✩ |

5Cr15MoV

|

|

| ✭✭✭✩✩ |

8Cr13MoV

|

|

8Cr15MoV(0.75% (C), 14% (Cr), 0.15% (Mo), 0.1% (V), 0.49% (Ni), 0.5% (Mn), 1% (Si)) Steel properties virtually identical to 8Cr13MoV but more corrosion resistant and slightly tougher. Comparable steel in AUS8 equivalent. Rockwell hardness 59 HRc. Perfect price/performance ratio. China / Ahonest Chankjiang |

||

| ✭✭✭✩✩ |

9Cr13CoMoV

|

|

| ✭✭✭✩✩ |

9Cr14MoV

|

|

| ✭✭✭✩✩ |

9Cr18MoV

|

|

| ✭✭✭✭✩ |

10Cr15CoMoV

|

|

T5MoV(0.5% (C), 14% (Cr), 0.35% (Mo), 0.15% (V), 0.15% (Co)) Stainless steel comparable to 440b Rockwell hardness up to 58 HRc France / Bonpertius |

||

| ✭✭✭✩✩ |

T6MoV

|

|

X-15TN(0.42% (C), 15.6% (Cr), 1.7% (Mo), 0.29% (V),0.3% (Ni), 0.46% (Mn), 0.23% (Si), 0.21% (N), which makes the steel very resistant to corrosion even in salt water, with excellent edge retention. Hardness 59HRc (Rockwell), French origin, patented by Aubert&Duval |

||

| ✭✭✭✭✩ |

N680 (X54CrMoNV18-1)

|

|

| ✭✭✭✭✩ |

N690 (1.4528; X105CrCoMo18-2; N690Co)

|

|

| ✭✭✭✭✩ |

N695 (1.4125, X102CrMo17)

|

|

| ✭✭✭✭✩ |

154CM (not to be confused with powder steel CPM-154, very identical - if not the same as ATS34)

|

|

| ✭✭✭✭✩ |

ATS-34 (very identical - if not the same as ATS34)

|

|

14-4CrMo (ATS34; 154CM)

|

||

ATS-55( 1% (C), 14% (Cr), 0.6% (Mo), 0.4% (Co), 0.2% (Cu), 0.5% (Mn), 0.4% (Si)) Very similar to ATS-34 steel, which has had the Molybdenum content reduced to make it easier to sharpen steel, but will not hold a blade as long as its bigger brother, ATS-34 steel. This steel was more or less only used by Spyderco in their early days of production. |

||

AUS-4(0.4% (C), 14% (Cr), 0.49% (Ni), 1%(Mn)) A very easy to grind steel that is relatively highly corrosion resistant, comparable in quality to 420-440B steel. Japan / Aichi Steel |

||

| ✭✭✭✩✩ |

AUS-6

|

|

| ✭✭✭✩✩ |

AUS-8

|

|

| ✭✭✭✭✩ |

AUS-10

|

|

| ✭✭✭✩✩ |

DSR1K6

|

|

| ✭✭✭✩✩ |

INOX; X55CrMoV14; 1.4110

|

|

| ✭✭✭✩✩ |

DAUPHINOX(0.52% (C), 15% (Cr), 0.6% (Mo), 0.5% (Mn), 0.6% (Si)) Victorinox high quality knives can only be made from the highest quality steel. It is only natural that steel brands are constantly evolving. However, in certain areas, both steel and knife manufacturers keep their secrets when it comes to the results of such developments. Among other factors, the way in which the steel is hardened has a significant influence on the final result. |

|

| ✭✭✭✭✩ |

12C27M

|

|

| ✭✭✭✭✩ |

12C27

|

|

| ✭✭✭✭✩ |

AEB-L (13C26; N611)(0.67% (C), 13% (Cr), 0.6% (Mn), 0.4% (Si)) Stainless steel similar in properties to Swedish 12C27M, very clean and very resistant to blade wear. Sandvik steel with increased wear and corrosion resistance, high hardness. The structure of the steel is very fine grained. Compared to 12C27 steel, higher hardness and wear resistance is met. It is recommended for surgical purposes. Manufacturer Austria / Bohler Uddeholm |

|

| ✭✭✭✭✩ |

14C28N

|

|

| ✭✭✭✭✩ |

19C27

|

|

| ✭✭✭✩✩ |

AN-58 (AN58 INOX)(0.45% (C), 13.5% (Cr), 0.01% (Mo),0.02% (V), 0.49% (Mn), 0.34% (Si)) Standard stainsless steel used by Nieto Co. |

|

| ✭✭✭✩✩ |

420MoV (X50CrMoV15; 1.4116)

|

|

| ✭✭✭✭✭ |

Lam.Cos(1.05% (C), 16% (Cr), 1.5% (Mo), 2.5% (Co), 0.25% (Ni), 0.25% (W)) The steel used and favoured by Fallkniven, where a harder and tougher steel with a hardness typically around 60 HRc, according to Rockwell, is nested in a sandwich of laminated steel in stainless steel, using 420J steel as the outer shell. |

|

| ✭✭✭✭✩ |

CTS-BD1

|

|

CTS-BD1N(0.95% (C), 17% (Cr), 0.5% (Mo), 1% (Mn), 1% (Si), 0.15% (N)) High-carbon stainless steel in an excellent ratio of resistance and toughness of the blade versus corrosion thanks to added nitrogen, even against weaker acids, ammonia, etc. It behaves similarly to tool steels. Compared to BD1 steel it has a higher hardness. Typical Rockwell hardness is 63 HRc. USA / Carpenter Technology |

||

95x18(1% (C), 19% (Cr), 0.6% (Ni), 0.8% (Mn), 0.8% (Si), 0.2% (Ti)) Russian version of 440C steel, contains an extra 0.2% Titanium. Typical Rockwell hardness up to 60 HRc. Russia / GOST |

||

| ✭✭✭✭✩ |

Niolox (Niolox Lohmann; 1.4153.03)

|

|

| ✭✭✭✭✩ |

Nitro-V

|

|

| ✭✭✭✭✩ |

VG1

|

|

| ✭✭✭✭✩ |

VG2

|

|

VG5(0.75% (C), 14% (Cr), 0.3% (Mo), 0.15% (V)) High purity Japanese steel, for entrylevel knives or kitchen knives. Similar properties and sharpenability to VG2, with higher carbon content. The steel is used specifically for the production of thin blades, which this steel can easily hold. Typical Rockwell hardness up to 59 HRc. Japan / Takefu Special Steel Company |

||

VG7(1% (C), 14% (Cr), 0.3% (Mo), 0.15% (V), 1.25% (W)) The higher percentage of very hard tungsten in the blend predisposes the knife in its fine microstructure to the perfect retention of the violet blade and the high hardness of the stainless steel. The toughness is still quite high in comparison, the blade endurance is impressive. Typical Rockwell hardness up to 61 HRc. Japan / Takefu Special Steel Company |

||

| ✭✭✭✭✭ |

VG10 (V-Kin-10)

|

|

VG10W( 1% (C), 15% (Cr), 1% (Mo), 0.25% (V), 1.55% (Co), 0.4% (W)) The more advanced VG10, which adds tungsten to the mix, increases the durability and hardness of the blade by about 20-25%. Typical Rockwell hardness up to 62 HRc. Japan / Takefu Special Steel Company |

||

1.2. Stainless steel produced by powder metallurgy

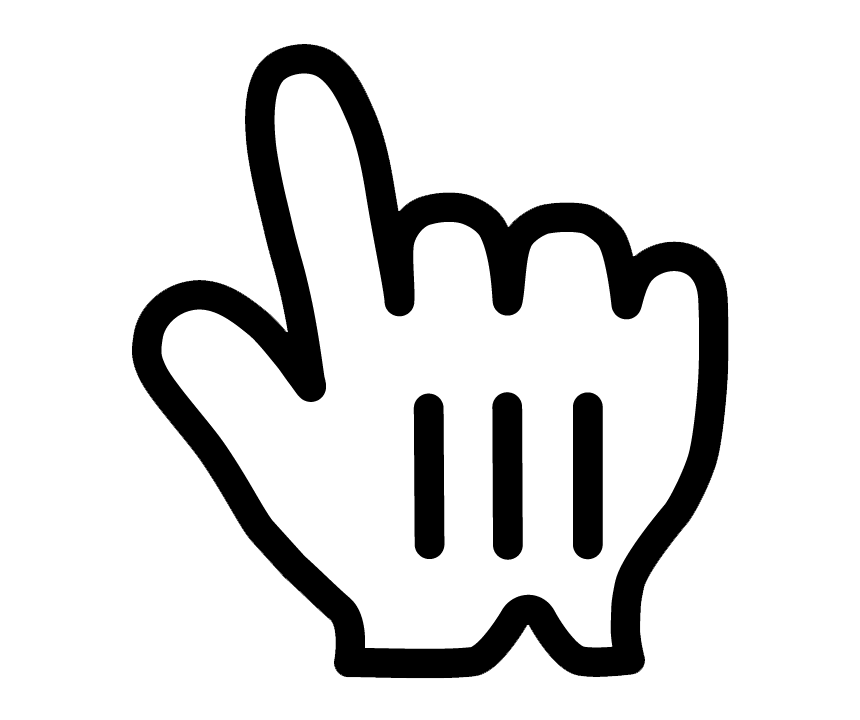

Powder stainless steels - powder technology that refines the composition and microstructure of the produced steel.

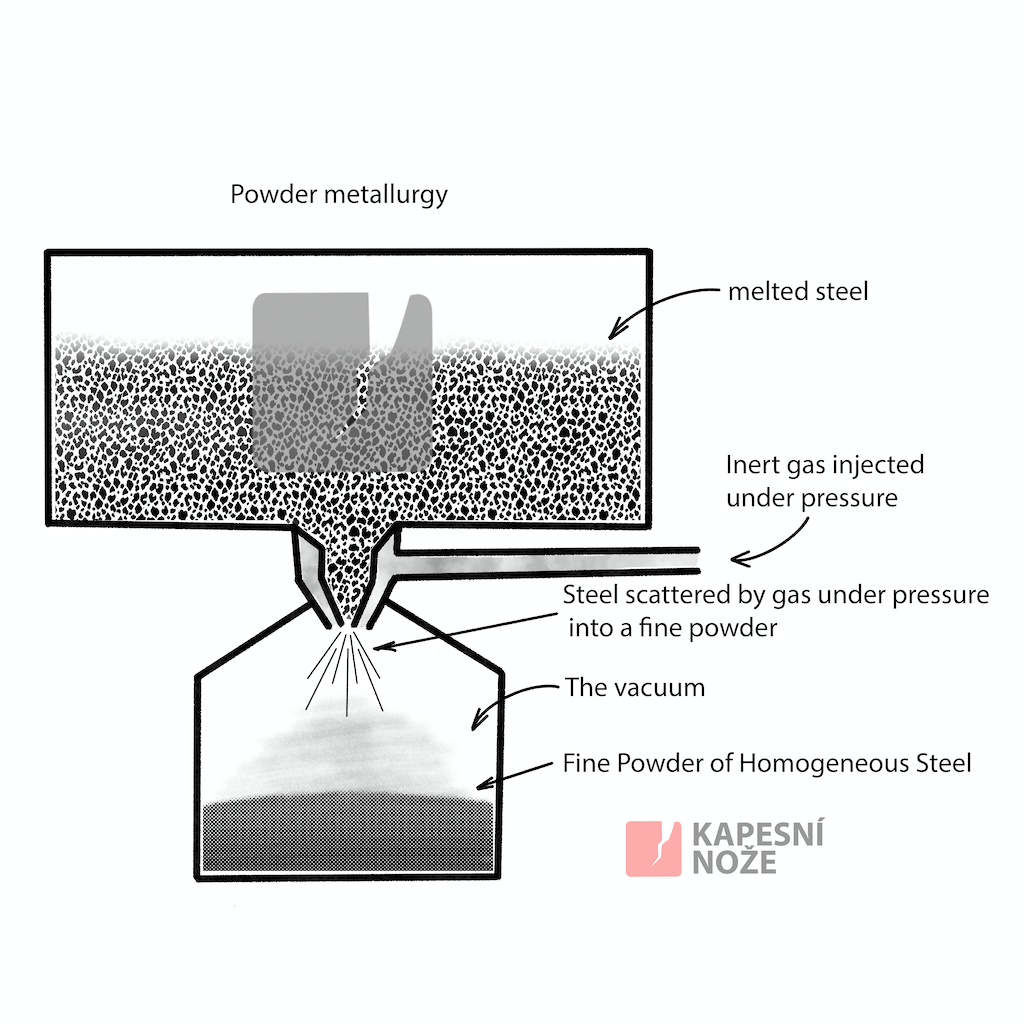

Powdered steel is predisposed by its composition to a very fine structure and the formation of very small carbides, which then exhibit much greater resistance and sharpness. The manufacturing process is simply that molten metal is poured through a small nozzle, where the action of a high-pressure gas jet through a small nozzle opening splashes the liquid metal into a spray mist of tiny droplets that essentially instantly compact into a solid form of very fine powder.

There are probably other technologies for creating powder steels, e.g. by grinding, crushing, etc., which are not detailed here.

| pict. Simplified drawing of the powder steel formation process |

This powder, in the form of powder particles with the same chemical composition, is combined under pressure, which produces a similar temperature to that of melting, into the desired compact material under vacuum in a special press. There is therefore no risk of contamination and the material is thus of high quality and clean. The carbide clusters are much smaller in size and this material exhibits approximately twice the fracture strength of conventional steels. So not only the chemical purity and much smaller carbide size, the composition structure is then more consistent. In short, a more advanced but more demanding technology that gives rise to the super steels.

what effect do have the chemical elements on the steel?

what effect do have the chemical elements on the steel?

| star rank | DIVISION OF STEEL GRADES |

|

✭✩✩✩✩ ✭✭✩✩✩ |

we do not offer steel of lower grades |

| ✭✭✭✩✩ | basic branded steel that offers quite decent performance for a lower price |

| ✭✭✭✭✩ | more advanced steel, which offers better properties than basic steel by a more balanced composition |

| ✭✭✭✭✭ | superior performance and exclusive properties of these steels |

440XH (Micro-Melt 440XH)(1.6 (C), 16% (Cr), 0.8% (Mo), 0.45% (V), 0.35% (Ni), 0.5% (Mn), 0.4% (Si)). Comparable to very hard 440C or corrosion resistant D2. The formation of fine-structured carbides is much higher in this steel than in 440C, therefore it also shows higher resistance, hardness and toughness compared to 440C. The powder steel, with its hardness of around 60 HRs (Rockwell hardness), therefore exhibits similar properties to the popular D2 cutlery steel. USA / Carpenter Technology |

||

| ✭✭✭✭✩ |

CPM-154

|

|

| ✭✭✭✭✩ |

CPM-S30V

|

|

| ✭✭✭✭✩ |

CPM-S35VN

|

|

| ✭✭✭✭✩ |

CPM-S45VN

|

|

CPM-S60V(formerly called CPM-440V) (2.15% (C), 17% (Cr), 0.4% (Mo), 5.5% (V), 0.4% (Mn)) One of the original super steels, due to its high Vanadium content, it is relatively resistant to abrasive materials, but is quite corrosion resistant. It offers excellent edge holding. Rockwell hardness typically around 60 HRc, however it is quite difficult to achieve this hardness on this steel. Very similar sharpness and edge retention to M390 steel. USA / Crucible Industries |

||

| ✭✭✭✭✭ |

CPM-S90V (CPM 420V; S90V)

|

|

| ✭✭✭✭✭ |

CPM-S110V (110V; S110V)

|

|

CPM-S125V(3.3% (C), 14% (Cr), 0.2% (Mo), 11.85% (V), 2.5% (Co), 0.2% (Ni), 0.25% (Mn), 0.9% (Si)). Very high wear resistance, originally intended for the dental surgical industry. Very difficult to machine, but has enormous edge life and high corrosion resistance. Resharpening, unless you have diamonds or Japanese natural stones, will be very difficult if not impossible. It is definitely not a steel for newcomers to sharpening. Due to the size of the primary carbide, a 1000 grit size grindstone is recommended as ideal. However, high edge life is the reward. Rockwell hardness is typically around 64 HRc. USA / Crucible Industries |

||

| ✭✭✭✭✩ |

RWL34 (RWL-34 PM; Z100CD14.4)

|

|

| ✭✭✭✭✭ |

CPM-20CV

|

|

| ✭✭✭✭✭ |

CPM-SPY27

|

|

CTS-204P( 1.9% (C), 20% (Cr), 1% (Mo), 4% (V), 0.35% (Mn), 0.6% (Si), 0.65% (W)) Powder steel produced by micromelt technology. Very similar to CPM-20CV or M390. Excellent wear resistance due to Vanadium carbide content. Uniform homogeneous structure ensures excellent wear resistance and toughness. A great choice, typically for higher model knives or limiters. Typical Rockwell hardness 62 HRc. USA / Carpenter Technology |

||

| ✭✭✭✭✩ |

CTS-XHP

|

|

| ✭✭✭✭✭ |

ELMAX (ELMAX Superclean)

|

|

| ✭✭✭✭✭ |

M390 MICRO CLEAN

|

|

M398 MICRO CLEAN(2.7% (C), 20% (Cr), 1% (Mo), 7.2% (V), 0.5% (Mn), 0.5% (Si), 0.7% (W)) New powder technology steel with more than 50% increase in carbide formation, i.e. overall around 30% fine carbide content (compared to M390 steel improvement.) Tougher and highly abrasion resistant more than M390 MICRO CLEAN. Even higher wear resistance. High corrosion resistance. As far as machining is concerned, it is not a very pliable steel. Typical Rockwell hardness is around 66 HRc. Austria - Sweden / Bohler Uddeholm |

||

SG2 (R2; SPGS)(1.45% (C), 16% (Cr), 3.3% (Mo), 2.2% (V), 0.4% (Mn), 0.5% (Si)) High-quality steel used by Takefu, Fallkniven or Shun. The high hardness of this powder steel predisposes it to high sharpness, used mainly in the production of kitchen knives. Typical Rockwell hardness up to 64HRc. Japan / Kobelco steel |

||

| ✭✭✭✭✭ |

SuperGold 2(The secret, unknown composition of stainless steel) Very clean, high quality powdered high-speed steel with no degrading properties or hardness. Similar in properties and toughness to carbon powder steel, but with a high degree of corrosion resistance. A fine, tough powder steel, reaching a Rockwell hardness of up to 63 HRc. Highly resistant to dulling. With excellent corrosion resistance and a high degree of wear resistance. The exact composition is not given by the manufacturer, from unverified sources the carbon content is 1.45% Carbon (C), 16% Chromium (Cr) Japan / Takefu Special Steel |

|

| ✭✭✭✭✩ |

LC200N (1.4108)

|

|

Vanax (Vanax SuperClean)(0.36% (C), 18.2% (Cr), 1.1% (Mo), 3.5% (V), 0.05% (Co), 0.18% (Ni), 0.3% (Mn), 0.3% (Si), 0.06% (W), 1.55% (N)) Swedish stainless steel powder, with nitrogen content that makes the steel immune to corrosion. Typical Rockwell hardness up to 62HRc. Austria / Bohler Uddeholm |

||

Cowry-X(3% (C), 20% (Cr), 1.7% (Mo), 0.9% (V)) Extremely high quality powder coated steel made by Mr. Ichiro Hattori. Rarely used, e.g. on a Fallkniven knife. Typical hardness is around 66 HRc according to Rockwell. Japan / Daido steel |

||

| ✭✭✭✭✭ |

ZDP189 (ZDP-189; 3C20CrMoW)

|

2. Carbon (High garbon content) steel

2.1. Tool steel

The steel has a high surface wear resistance, it is classified into A (air hardened), O (oil hardened), D (high carbon steels with increased chromium content). They offer relatively high wear resistance and medium toughness. Excellent sharpenability and are very popular as knife steels.

what effect do have the chemical elements on the steel?

what effect do have the chemical elements on the steel?

| star rank | DIVISION OF STEEL GRADES |

|

✭✩✩✩✩ ✭✭✩✩✩ |

we do not offer steel of lower grades |

| ✭✭✭✩✩ | basic branded steel that offers quite decent performance for a lower price |

| ✭✭✭✭✩ | more advanced steel, which offers better properties than basic steel by a more balanced composition |

| ✭✭✭✭✭ | superior performance and exclusive properties of these steels |

O1 ( Carpenter O1; 100MnCrW4; ČSN 19314; 1.2825; SKS3)(0.9% (C), 0.5% (Cr), 0.2- % (V), 1.2% (Mn), 0.5 % (W)) Tool steel with the highest hardening stability. Good wear resistance and good edge life. Typical Rockwell hardness up to 65 HRc. |

||

O2 (AISI O2; 90MnCrV8; SKS93; ČSN 19312; 1.2842; K720)(0.95% (C), 0.35% (Cr), 0.3% (Mo), 0.3% (V), 0.3% (Ni), 1.8 % (Mn), 0.3% (Si)) Oil-hardened tool steel offers decent durability for medium to heavy use. Typical Rockwell hardness up to 64 HRc. |

||

| ✭✭✭✭✩ |

A2 (X100CrMoV5 ;ČSN 19571PH; SKD12; 1.2363; K305)

|

|

A6 (70MnMoCr8; 1.2824; UHN1550)(0.75% (C), 1.2% (Cr), 1.4% (Mo), 2.5% (Mn)) Decent wear resistance, not very often used steel. |

||

| ✭✭✭✭✩ |

D2 (X155CrMoV121; ČSN 19573; SKD11; 1.2379; AIRDI 15; K110)

|

|

S7 (50CrMoV13; ČSN 19550; 1.2357)(0.55% (C), 3.5% (Cr), 1.8% (Mo), 0.3% (V), 0.8% (Mn), 1% (Si),) Steel has a very high resistance to breakage, but a moderate resistance to wear and dulling. Typical Rockwell hardness up to 61 HRc. |

||

T1 (X75WCrV18-4; SKH2; ČSN 19824; 1.3355)(0.8% (C), 4% (Cr), 1.3% (V), 0.3% (Ni), 0.4% (Mn), 0.4% (Si), 18.75% (W)) High speed tool steel with a very high content of very hard tungsten. Typical Rockwell hardness up to 65 HRc. |

||

M1 (s1-8-1; SKH50; 1.3346)(0.88% (C), 4% (Cr), 9.2% (Mo), 1.35% (V), 0.3% (Ni), 0.4% (Mn), 0.5% (Si),2.1% (W)) Molybdenum tungsten steel, a relatively tough high-speed tool steel. Typical Rockwell hardness up to 65 HRc. |

||

M2 (s6-5-2; ČSN 19830; SKH9; 1.3342)(1.05% (C), 4.5% (Cr), 5.5% (Mo), 2.2% (V), 0.3% (Ni), 0.4% (Mn), 0.45% (Si), 6.75% (W)) Excellent wear and dulling resistance and decent toughness. Typical Rockwell hardness up to 65 HRc. |

||

M35 (s6-5-2-5; ČSN 19852; SKH55; 1.3243)(0.95% (C), 4.5% (Cr), 5.25% (Mo), 2.15% (V), 0.4% (Ni), 0.4% (Mn), 0.4% (Si), 6.75% (W)) The impressive combination of wear resistance and high hardness of this tool steel makes it suitable for demanding applications. Typical Rockwell hardness up to 65 HRc. |

||

W1 (C100W1; ČSN 19133; SK3; 1.1645; K970)(1.5% (C), 0.15% (Cr), 0.1% (Mo), 0.1% (V), 0.2% (Ni), 0.4% (Mn), 0.4% (Si), 0.15% (W)) Water hardenable tool steel has excellent wear resistance and high toughness. Typical Rockwell hardness up to 68 HRc. |

||

H13 (X40CrMoV51; ČSN 19554; SKD61; 1.2344; W302)(0.45% (C), 5.5% (Cr), 1.75% (Mo), 1.2% (V), 0.3% (Ni), 0.5% (Mn), 1.2% (Si)) Chromium molybdenum vanadium tool steel characterized by decent hardenability and excellent toughness. Typical Rockwell hardness up to 54 HRc. |

||

SK3 (W1; ČSN19133)(1.1% (C), 0.3% (Cr), 0.25% (Ni), 0.5% (Mn), 0.35% (Si)) Carbon steel, made in Japan, basically similar to W1 steel, high toughness and wear resistance. Typical Rockwell hardness up to 61HRc. Japan / Nisshin |

||

SK4 (SK95; 1.1545)(1% (C), 0.3% (Cr), 0.25% (Ni), 0.5% (Mn), 0.35% (Si)) High toughness and wear resistance. Typical Rockwell hardness up to 60HRc. Japan / Nisshin |

||

| ✭✭✭✩✩ |

SK5 (1.1525; SK85)

|

2.2. Carbon steel (High garbon content)

what effect do have the chemical elements on the steel?

what effect do have the chemical elements on the steel?

| star rank | DIVISION OF STEEL GRADES |

|

✭✩✩✩✩ ✭✭✩✩✩ |

we do not offer steel of lower grades |

| ✭✭✭✩✩ | basic branded steel that offers quite decent performance for a lower price |

| ✭✭✭✭✩ | more advanced steel, which offers better properties than basic steel by a more balanced composition |

| ✭✭✭✭✭ | superior performance and exclusive properties of these steels |

80CrV2 (ČSN 19419; 1.2235)(0.85% (C), 0.6% (Cr), 0.1% (Mo), 0.25% (V), 0.4% (Ni), 0.5% (Mn), 0.3% (Si)) Very decent edge life, but still sharpenable in the field. It offers a perfect balance between hardness and toughness. Typical Rockwell hardness up to 61 HRc. Germany / Krupp |

||

Caldie(0.7% (C), 5% (Cr), 2.3% (Mo), 0.5% (V), 0.5% (Mn), 0.2% (Si)) Steel resistant to chipping and cracks, suitable for larger blades. Typical Rockwell hardness up to 62 HRc. Sweden / Bohler Uddeholm |

||

| ✭✭✭✭✭ |

Sleipner

|

|

| ✭✭✭✭✩ |

1095 ( SUP4; 1.1275)

|

|

1095CroVan (1095CV)(1.1% (C), 0.6% (Cr), 0.06% (Mo), 0.25% (V), 0.25% (Ni), 0.5% (Mn), 0.25% (Si)) Increased wear resistance and increased toughness compared to the basic version 1095. Typical Rockwell hardness up to 60 HRc. USA / Sharon Steel |

||

52100 (100Cr6; ČSN14100; SUJ2; 1.3505)(1.1% (C), 1.6% (Cr), 0.3% (Ni), 0.45% (Mn), 0.3% (Si)) Similar steel to 5160, but with better edge retention but less toughness. Typical Rockwell hardness up to 59 HRc. |

||

1084 (1.0616)(0.93% (C), 0.9% (Mn)) Simple carbon steel with medium wear resistance. Typical Rockwell hardness up to 59 HRc. |

||

| ✭✭✭✩✩ |

1080 (AISI 1080; 80Mn4; 1.1259; 75A)

|

|

| ✭✭✭✩✩ |

1075 (1.1248)

|

|

| ✭✭✭✩✩ |

1060 (AISI 1060; C60; ČSN12061; 1.0601; 60)

|

|

| ✭✭✭✩✩ |

1065 (AISI 1065; XC65; 1.1230)

|

|

| ✭✭✭✩✩ |

1045 (ČSN19083; 1.1191)

|

|

| ✭✭✭✩✩ |

5160 (60Cr3; 1.7177)

|

|

| ✭✭✭✩✩ |

65Mn (AISI 1066)

|

|

CruForgeV (1086V)(1.05% (C), 0.5% (Cr), 0.75% (V), 0.75% (Mn)) Ideal steel for knife makers who forge their knives. Similar properties to W1 or O1 steel. Typical Rockwell hardness up to 64HRc. USA / Crucible Industries |

||

| ✭✭✭✭✭ |

Y7XR

|

|

V-Toku1 (Takefu V1 Special)(1.15% (C), 0.35% (Cr), 0.2% (V),2.25% (W)) The high hardness and resistance of the blade, also against chipping, is the main feature of this very pure steel typically used for chef's knives. Typical Rockwell hardness up to 64 HRc. Japan / Takefu Special Steel |

||

V-Toku2 (Takefu V2 Special)((1.05% (C), 0.25% (Cr), 0.2% (V),1.25% (W)) The high hardness and resistance of the blade, also against chipping, is the main feature of this very pure steel typically used for chef's knives. Typical Rockwell hardness up to 62 HRc. Japan / Takefu Special Steel |

||

| ✭✭✭✭✩ |

Shiro2 (Takefu Shiro 2)

|

|

V-Gin1 (Stainless Chromax; V1 Silver)(1.15% (C), 5% (Cr), 1% (Mo), 0.5% (V), 0.25% (Ni), 0.9% (Mn), 0.4% (Si)) Very pure steel, made in Japan from Swedish ore. Typical Rockwell hardness up to 61HRc. Japan / Takefu special Steel |

||

Gin2 (Stainless Chromax)(0.9% (C), 7.5% (Cr)) Steel less susceptible to corrosion due to chromium content. Typical Rockwell hardness up to 62HRc. Japan / Takefu steel Special |

||

V-Gin3B (Stainless Chromax ; 3B Silver V)(0.85% (C), 6.5% (Cr), 0.8% (Mo), 0.4% (V), 0.5% (Ni), 0.5% (W)) Steel less susceptible to corrosion due to its chromium content, relatively hard, used extensively for kitchen knives due to its excellent sharpenability and blade life. Typical Rockwell hardness up to 62HRc. Japan / Takefu steel Special |

||

8670 (AISI 8670; 1.2703)(0.75% (C), 0.5% (Cr), 0.15% (Mo), 1% (Ni), 0.6% (Mn), 0.35% (Si)) Steel used since WWII, tough, with pretty decent wear resistance. Typical Rockwell hardness up to 61HRc. |

||

Yellow steel (Kigami #2; Yellow paper steel)(1.15% (C), 0.3% (Mn), 0.2% (Si)) Very hard medium grade steel used mainly for kitchen knives. Typical Rockwell hardness up to 61HRc. Japan / Hitachi (Yasugi) |

||

Yellow steel (Kigami #3; Yellow paper steel)(0.9% (C),0.3% (Mn), 0.2% (Si)) Medium grade steel is used for kitchen knives. Typical Rockwell hardness up to 60HRc. Japan / Hitachi (Yasugi) |

||

WhiteSteel #2 (Shirogami #2; Shiro-Ko 2)(1.15% (C) 0.3% (Mn), 0.25% (Si)) Very decent blade life and high hardness, can produce a very fine edge. Widely used in kitchen knives. Typical Rockwell hardness up to 61HRc. Japan / Hitachi (Yasugi) |

||

| ✭✭✭✭✩ |

WhiteSteel #1 (Shiroogami #1)

|

|

| ✭✭✭✭✭ |

Blue steel #2 (Aogami#2, Ao-ni ko)(1.15% (C), 0.5% (Cr), 0.3% (Mn), 0.2% (Si), 1.5% (W)) Very clean and high quality steel, with high hardness and the possibility of a very fine edge. Used on kitchen knives. Very maintainable sharpness, for example, blade can be easily maintained just on a |

|

| ✭✭✭✭✭ |

Blue steel #1 (Aogami #1, Ao-ichi ko)

|

|

BlueSuper steel (Super Blue, Aogami super)(1.5% (C), 0.5% (Cr), 0.5% (V), 0.3% (Mn), 0.2% (Si), 2.5% (W)) One of the finest steels, typical for kitchen knives, with very high hardness and fineness of the blade. Although it has a lower toughness than Blue1 and Blue2 steels, it has the highest hardness and wear resistance of these steels. A royal steel, with medium sharpness. With the use of the blade can also be easily maintained on a |

||

| ✭✭✭✭✩ |

S600 (Bohler S600; 1.3343)(0.9% (C), 4.1% (Cr), 1.8% (V), 5% (Mn), 6.2% (W)) Quick-cutting tool steel, expert steel with high wear resistance, stable toughness and relatively good machinability. Typical Rockwell hardness up to 64HRc. Sweden / BOHLER-UDDEHOLM |

2.3. High carbon content steel made with powder metalurgy

Powder steels - powder technology that refines the composition and microstructure of the produced steel.

Powdered steel is predisposed by its composition to a very fine structure and the formation of very small carbides, which then exhibit much greater resistance and sharpness. The manufacturing process is simply that molten metal is poured through a small nozzle, where the action of a high-pressure gas jet through a small nozzle opening splashes the liquid metal into a spray mist of tiny droplets that essentially instantly compact into a solid form of very fine powder.

There are probably other technologies for creating powder steels, e.g. by grinding, crushing, etc., which are not detailed here.

| pict. Simplified drawing of the powder steel formation process |

This powder, in the form of powder particles with the same chemical composition, is combined under pressure, which produces a similar temperature to that of melting, into the desired compact material under vacuum in a special press. There is therefore no risk of contamination and the material is thus of high quality and clean. The carbide clusters are much smaller in size and this material exhibits approximately twice the fracture strength of conventional steels. So not only the chemical purity and much smaller carbide size, the composition structure is then more consistent. In short, a more advanced but more demanding technology that gives rise to the super steels.

what effect do have the chemical elements on the steel?

what effect do have the chemical elements on the steel?

| star rank | DIVISION OF STEEL GRADES |

|

✭✩✩✩✩ ✭✭✩✩✩ |

we do not offer steel of lower grades |

| ✭✭✭✩✩ | basic branded steel that offers quite decent performance for a lower price |

| ✭✭✭✭✩ | more advanced steel, which offers better properties than basic steel by a more balanced composition |

| ✭✭✭✭✭ | superior performance and exclusive properties of these steels |

| ✭✭✭✭✭ |

CPM REX M4 ( CPM-M4; M4; SKH54; 1.3394)

|

|

| ✭✭✭✭✭ |

Maxamet ( Micro-Melt Maxamet)

|

|

| ✭✭✭✭✭ |

CPM-3V (3V)

|

|

| ✭✭✭✭✭ |

CPM-15V (15V)

|

|

| ✭✭✭✭✭ |

CPM-MagnaCut (MagnaCut)

|

|

| ✭✭✭✭✩ |

CPM CruWear (CRU-WEAR; CruWear; 1.2895)

|

|

K490 MICRO CLEAN(1.4% (C), 6.4% (Cr), 1.5% (Mo), 3.7% (V), 3.5% (W)) Powder steel with unspecified Niobium content, which forms very fine and hard carbides. The toughness of this steel is up to twice that of M4 steel, while maintaining wear resistance. Typical Rockwell hardness up to 65HRc. Sweden / BOHLER-UDDEHOLM |

||

| ✭✭✭✭✭ |

K390 MICRO CLEAN

|

|

K294 MICRO CLEAN(2.45% (C), 5.2% (Cr), 1.3% (Mo), 9.7% (V), 0.5% (Mn), 0.9% (Si)) The very high wear resistance of this steel, due to its high Vanadium content. Medium toughness and relatively hard machinability of this Swedish powder metallurgy steel. It is used when the main emphasis is on really high wear resistance. Typical Rockwell hardness up to 63HRc. Sweden / BOHLER-UDDEHOLM |

||

K190 MICRO CLEAN(2.3% (C), 12.5% (Cr), 1.1% (Mo), 4% (V), 0.3% (Mn), 0.6% (Si)) Very pure steel produced by powder metallurgy. Typical Rockwell hardness up to 65HRc. Sweden / BOHLER-UDDEHOLM |

||

CPM REX76(1.5% (C),3.75% (Cr), 5.25% (Mo), 3.10% (V), 8.5% (Co), 0.3% (Mn), 0.3% (Si), 9.75% (W)) A powdered high speed steel very similar to REX45, with a higher tungsten content to give higher hardness. Typical Rockwell hardness up to 67 HRc. USA / Crucible |

||

CPM REX 121(3.4% (C), 4% (Cr), 5% (Mo),9.5% (V), 9% (Co), 10% (W)) One of the toughest knife steels with one of the highest wear resistance. A highly demanding steel to sharpen, with a tremendous hardness far above other steels. Vanadium, cobalt and tungsten content resulting in very hard machinability even on ceramic grinding belts. Typical Rockwell hardness up to 71 HRc. USA / Crucible |

||

CPM REX45 (Vanadis 30; Bohler S590; HAP40)(1.3% (C),4.05% (Cr), 5% (Mo), 3.05% (V), 8% (Co), 0.3% (Mn), 0.5% (Si), 6.25% (W)) Powdered steel is slightly less abrasion resistant than e.g. M4 steel, but thanks to the addition of Cobalt it is much harder. Typical Rockwell hardness up to 66 HRc. USA / Crucible |

||

Z-Max(2% (C), 4% (Cr), 5% (Mo), 5% (V), 9% (Co), 0.12% (Si), 10% (W)) Super highsspeed cutting powder steel. High resistance to wear and dulling. However, it is demanding to machine and sharpen. Typical Rockwell hardness up to 68HRc. Germany / ZAPP |

||

Vanadis8(2.3% (C), 4.8% (Cr), 3.6% (Mo), 8% (V), 0.4% (Mn), 0.4% (Si)) Improved steel, made by powder metallurgy, quite resistant to chipping of the blade. Very good wear resistance. Typical Rockwell hardness up to 65HRc. Sweden / Bohler Uddeholm |

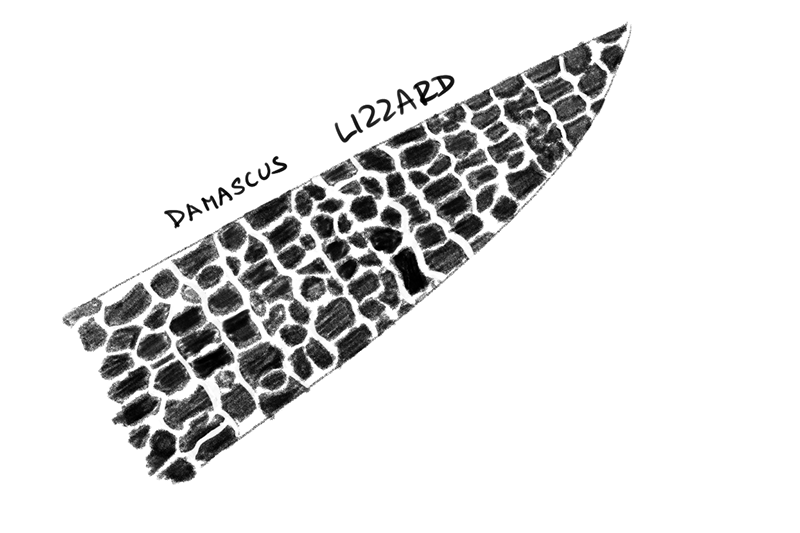

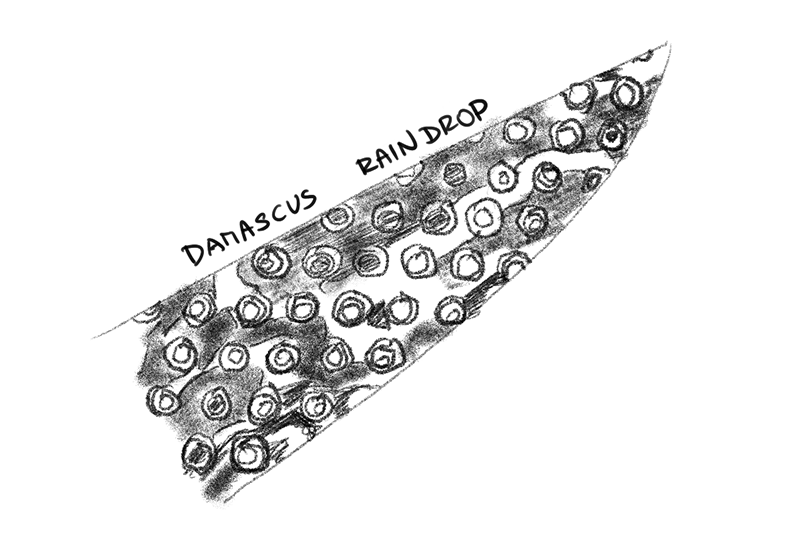

3. Damascus steel

Damascus steel

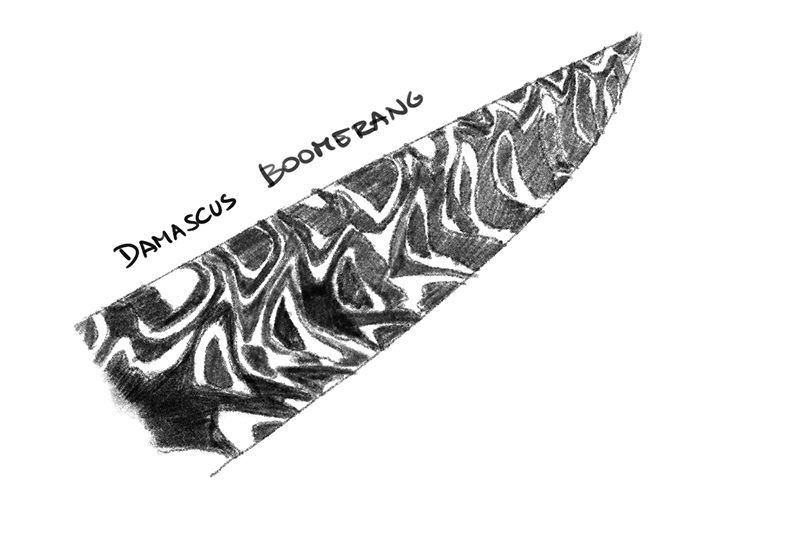

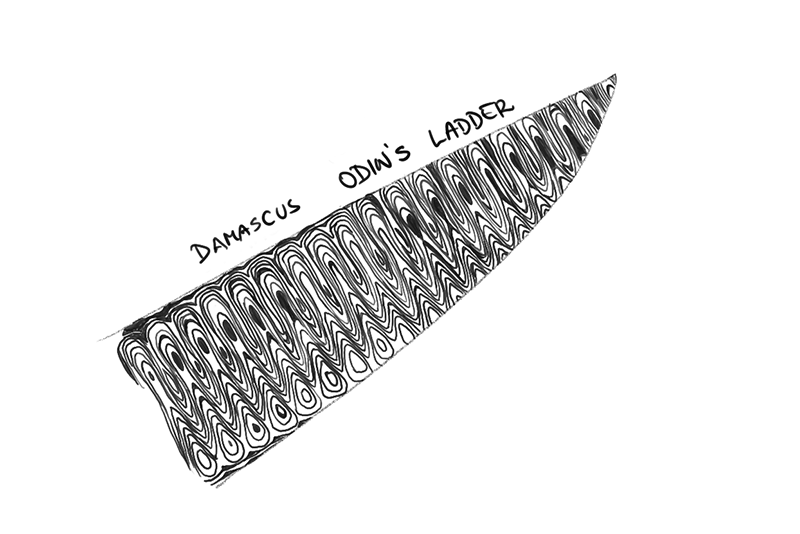

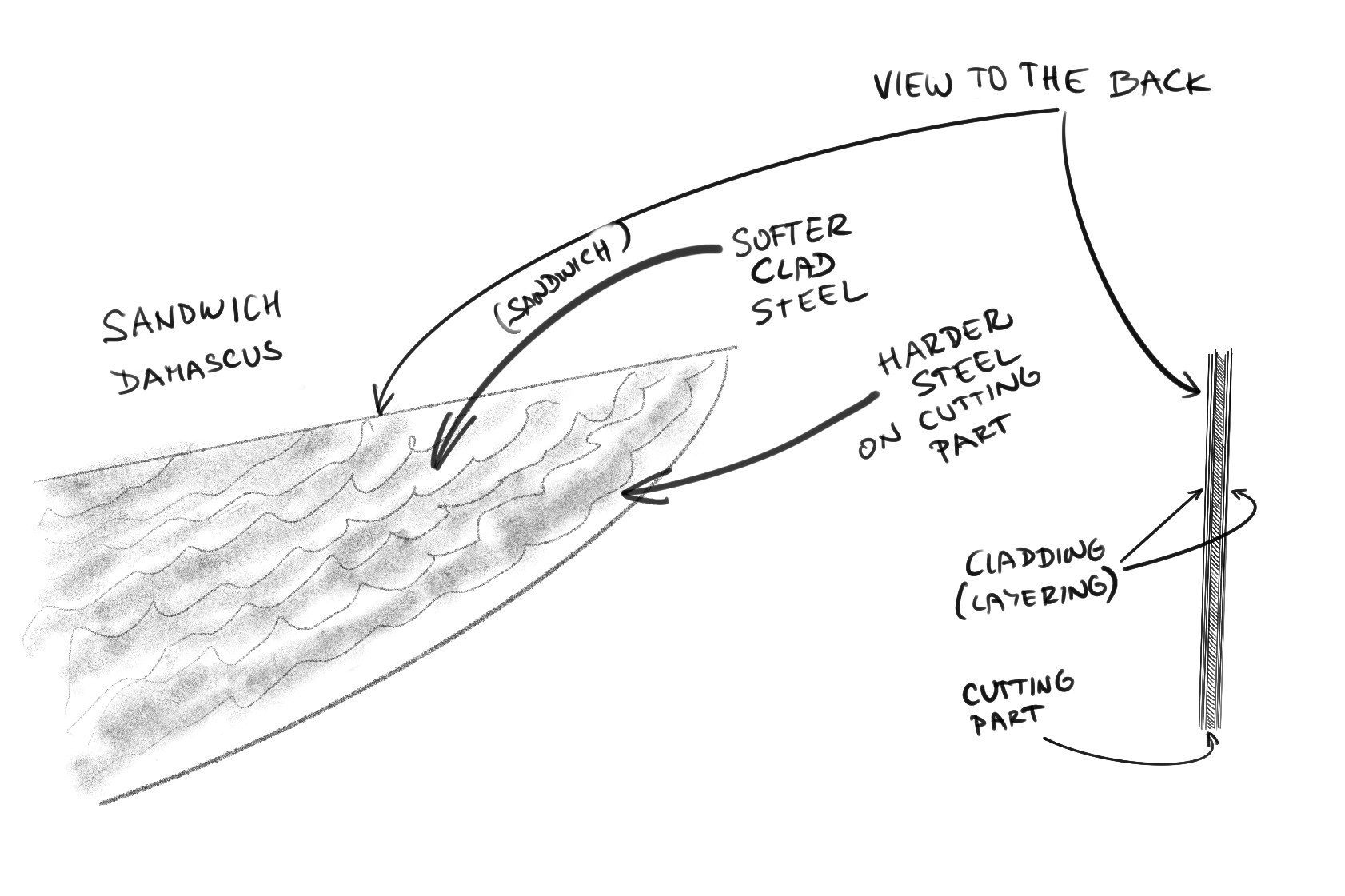

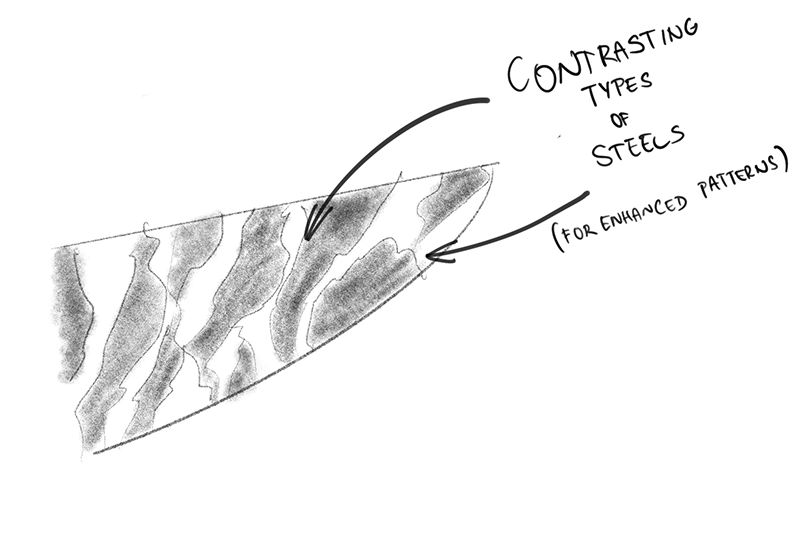

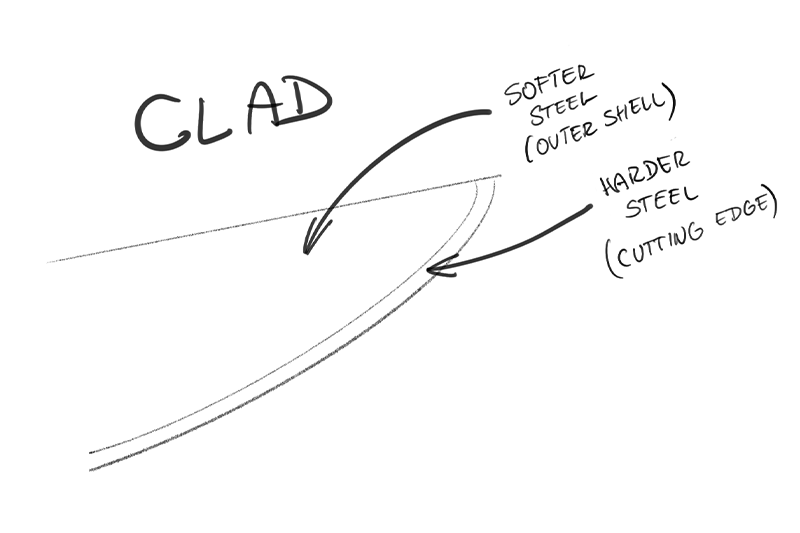

The steel, worked and forged in Damascus, was a masterful example of the skill of the local smiths and is still known today.These craftsmen, who were able to combine contrasting steels into shapes and decorative variations and different motifs, often enhanced the quality of the blades by forging.The workmanship and functionality of these blades were second to none.They are a non-homogeneous but more or less regular internal structure, with alternating layers of at least two different types of steel. Nowadays, damascus blades are available in simple carbon steel variants, stainless steel variants and stacked sandwich variants of the damascus design, i.e. layering. Typically, they are formed with a double material if some more distinctive pattern is desired, or perhaps even simple functionality where the cutting part is left harder and the sheathing made of e.g. stainless steel for greater corrosion resistance. These combinations and motifs are countless.

| Fig. Drawing of sandwich functional damask | ||

| star rank | DIVISION OF STEEL GRADES |

|

✭✩✩✩✩ ✭✭✩✩✩ |

we do not offer steel of lower grades |

| ✭✭✭✩✩ | basic branded steel that offers quite decent performance for a lower price |

| ✭✭✭✭✩ | more advanced steel, which offers better properties than basic steel by a more balanced composition |

| ✭✭✭✭✭ | superior performance and exclusive properties of these steels |

| ✭✭✭✭✩ |

PMC27 (PMC-27)

|

|||||

| ✭✭✭✩✩ |

Pakistan Damascus

|

|||||

|

||||||

| Fig. Typical design of Pakistani version of Damascus steel | ||||||

| ✭✭✭✭✩ |

Stainless steel Damascus

|

|||||

|

||||||

| Fig. Some of the drawings created as decorative motifs for stainless steel damasks | ||||||

| ✭✭✭✭✭ |

Clad / Sandwich damascus / San-Mai

|

|||||

|

||||||

| Fig. Variant of functional damascus, where the core is made of harder, high quality steel and the sheath is made of softer material, which gives the blade flexibility, typical for Japanese knives | ||||||

And how to find your way around all this? Let's try to keep it simple. There are four qualities we require from steel. So to some extent, for example.

1. corrosion resistance, i.e. rust resistance

2. edge retention (often influenced by the hardness of the steel)

3. toughness, i.e. how resistant the steel is to the formation of teeth on the blade, or breakage

4. ease of sharpening or resharpening, here again, the harder the steel, the harder it is to sharpen.

The top row of this table can be clicked to sort the order of the most popular steels according to desired preferences, i.e. sorting by corrosion resistance, toughness, ease of sharpening and blade life.

1 - worse, 10 - best (the price is exactly the opposite, we welcome cheaper)

| the best known steel types | Endurance of the sharpness | Toughness | Corrosion Resistance | Ease of sharpening | Steel Grade / Price |

|---|---|---|---|---|---|

| Maxamet | 10 | 2 | 4 | 1 | 10 |

| CPM-S90V | 9 | 4 | 8 | 2 | 9 |

| CPM-S110V | 8 | 4 | 9 | 3 | 8 |

| CPM-20CV | 7 | 4 | 9 | 5 | 5 |

| M390 | 7 | 4 | 9 | 5 | 8 |

| CPM MagnaCut | 5 | 9 | 10 | 6 | 8 |

| CPM-M4 | 9 | 7 | 2 | 3 | 8 |

| CPM-CruWear | 8 | 5 | 6 | 6 | 6 |

| ZDP-189 | 10 | 3 | 7 | 2 | 10 |

| CTS-204P | 7 | 4 | 9 | 5 | 8 |

| Elmax Micro Clean | 6 | 4 | 8 | 6 | 8 |

| CPM-10V | 9 | 5 | 4 | 3 | 7 |

| CPM-S30V | 6 | 4 | 8 | 5 | 5 |

| CPM-154 | 5 | 5 | 7 | 7 | 7 |

| CPM-4V | 5 | 7 | 4 | 6 | 6 |

| AEB-L | 3 | 10 | 7 | 8 | 3 |

| Sleipner | 6 | 6 | 3 | 8 | 4 |

| K390 | 9 | 5 | 4 | 3 | 6 |

| CTS-XHP | 6 | 5 | 7 | 6 | 5 |

| CPM-3V | 5 | 9 | 6 | 7 | 7 |

| CPM-S35V | 5 | 5 | 8 | 6 | 6 |

| LC200N | 3 | 9 | 10 | 8 | 6 |

| 154CM | 5 | 4 | 7 | 7 | 3 |

| N690 | 5 | 4 | 8 | 7 | 4 |

| CTS BD1N | 4 | 4 | 9 | 8 | 4 |

| A2 | 3 | 7 | 3 | 9 | 4 |

| O1 | 2 | 5 | 1 | 9 | 3 |

| D2 | 5 | 4 | 5 | 6 | 4 |

| VG10 | 5 | 4 | 8 | 7 | 5 |

| 14C28N | 3 | 9 | 9 | 8 | 3 |

| 1095 | 2 | 5 | 1 | 10 | 3 |

| H1 | 1 | 10 | 10 | 10 | 4 |

| 440C | 5 | 4 | 8 | 7 | 2 |

| 440A | 4 | 4 | 9 | 8 | 1 |

| 8Cr13MoV | 3 | 6 | 7 | 8 | 2 |

| CTS-BD1 | 5 | 5 | 7 | 7 | 3 |

| 420 | 3 | 10 | 8 | 9 | 1 |

| AUS-8 | 3 | 6 | 7 | 8 | 3 |

what effect do the elements have on the steel?

what effect do the elements have on the steel?

Stainless steel

| stainless steel | C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| 420 (AISI 420; X20Cr13; 1.4021; ČSN17022; SUS420J1) | 0,15% | 14.00% | x | 1.00% | x | x | x | x | x | 1.00% | x | ≤55 | 30° 1100x (uton) | USA / Carpenter Technology |

| 420J2 (AISI 420M; 1.4028; SUS420J2; ČSN17023) | 0.35% | 13.00% | x | 1.00% | x | 1.00% | x | x | x | 1.00% | x | ≤53 | ||

| 420HC; TruSharp | 0.45% | 13.00% | 0.6% | 0.4% | x | x | 0.3% | x | x | 0.3% | 0.00% | ≤58 | 10° 425x | USA / Latrobe Specialty steel company |

| 440A (AISI 440A; X65CrMo14; 1.4109) | 0.75% | 18.00% | 0.75% | 1.00% | x | x | x | x | x | 1.00% | x | ≤56 | 35° 375x ; 30° 600x | USA / Carpenter Technology |

| 440B (AISI 440B; X90CrMoV18; 1.4112) | 0.95% | 18.00% | 0.75% | 1.00% | x | x | x | x | x | 1.00% | x | ≤58 | USA / Carpenter Technology | |

| 440C (AISI 440C; N685; X105CrMo17; ČSN 17042; 1.4125) | 1.2% | 18.00% | 0.75% | 1.00% | x | x | x | x | x | 1.00% | x | ≤60 | 36° 360x ; 30° 1300x | USA / Carpenter Technology |

| W.1.4034 (X46Cr13; N540; ČSN 17029) | 0.46% | 13.00% | 0.14% | 0.47% | x | 0.28% | x | x | x | 0.33% | x | ≤53 | ||

| 3Cr13 | 0.35% | 14.00% | x | 1.00% | x | 0.6% | x | x | x | 1.00% | x | ≤54 | ||

| 5Cr15MoV | 0.5% | 15.00% | 0.6% | 0.4% | x | x | 0.1% | x | x | x | x | ≤56 | ||

| 8Cr13MoV | 0.8% | 14.00% | 0.15% | 1.00% | x | 0.2% | 0.1% | x | x | 1.00% | x | ≤59 | 30° 900x | |

| 8Cr15MoV | 0.75% | 14.00% | 0.15% | 0.5% | x | 0.49% | 0.1% | x | x | 1.00% | x | ≤59 | ||

| stainless steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| 9Cr13CoMoV | 0.85% | 13.5% | 0.2% | 1.00% | 1.00% | x | 0.2% | x | x | 1.00% | x | ≤60 | ||

| 9Cr14MoV | 0.9% | 14.00% | 0.25% | 0.6% | x | x | 0.15% | x | x | 0.6% | x | ≤60 | ||

| 9Cr18MoV | 0.95% | 18.00% | 1.00% | 0.8% | x | 0.1% | x | x | x | 0.8% | x | ≤60 | ||

| 10Cr15CoMoV | 1.05% | 15.00% | 1.2% | 0.5% | 1.5% | 0.25% | 0.3% | x | x | x | x | ≤62 | ||

| T5MoV | 0.5% | 14.00% | 0.35% | x | x | x | 0.15% | x | x | x | x | ≤58 | france / Bonpertius | |

| T6MoV | 0.6% | 14.2% | 0.65% | x | x | x | 0.1% | x | x | 1.00% | x | ≤56 | france / Bonpertius | |

| X-15TN | 0.42% | 15.6% | 1.7% | 0.46% | x | 0.3% | 0.29% | x | x | 0.23% | x | ≤60 | france / Aubert&Duval | |

| N680; X54CrMoNV18-1 | 0.54% | 17.3% | 1.1% | 0.4% | x | x | 0.1% | 0.2% | x | 0.45% | x | ≤58 | austria / Bohler Uddeholm | |

| N690; W1.4528; X105CrCoMo18-2, N690Co | 1.08% | 17.3% | 1.1% | 0.4% | 1.5% | x | 0.1% | x | x | 0.4% | x | ≤60 | 40° 290x ; 30° 1400x | austria / Bohler Uddeholm |

| N695; 1.4125;X102CrMo17 | 1.2% | 18.00% | 0.65% | 1.00% | x | 0.75% | x | x | x | 1.00% | x | ≤60 | austria / Bohler Uddeholm | |

| 154CM | 1.05% | 14.00% | 4.00% | 0.5% | x | x | x | x | x | 0.3% | x | ≤61 | 30° 2200x | USA / Crucible Industries |

| stainless steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| ATS-34 | 1.05% | 14.00% | 4.00% | 0.4% | x | x | x | x | x | 0.35% | x | ≤61 | japan / Hitachi | |

| 14-4CrMo (ATS34; 154CM) | 1.05% | 14.00% | 4.00% | 0.5% | x | x | x | x | x | 0.3% | x | ≤61 | USA / Latrobe Specialty steel company | |

| ATS-55 | 1.00% | 14.00% | 0.6% | 0.5% | 0.4% | x | x | x | x | 0.4% | 0.2% (Cu) | ≤61 | ||

| AUS-4 | 0.4% | 14.00% | x | 1.00% | x | 0.49% | x | x | x | x | x | ≤57 | japan / Aichi Steel | |

| AUS-6 | 0.6% | 14.00% | x | 1.00% | x | 0.49% | 0.2% | x | x | 1.00% | x | ≤57 | japan / Aichi Steel | |

| AUS-8 | 0.75% | 14.00% | 0.2% | 0.5% | x | 0.49% | 0.2% | x | x | 1.00% | x | ≤59 | 30° 850x | japan / Aichi Steel |

| AUS-10 | 1.1% | 14.00% | 0.3% | x | x | 0.49% | 0.27% | x | x | 1.00% | x | ≤60 | japan / Aichi Steel | |

| DSR1K6 | 0.6% | 14.00% | x | 1.00% | x | 0.49% | 0.2% | x | x | 1.00% | x | ≤58 | japan / Daido steel | |

| INOX; X55CrMo14; W1.4110 | 0.75% | 16.00% | 0.8% | 0.9% | x | x | x | x | x | 0.7 | x | ≤60 | 40° 400x ; 30° 750x | germany / Krupp |

| DAUPHINOX | 0.52% | 15.00% | 0.6% | 0.5% | x | x | x | x | x | 0.6 | x | ≤60 | VICTORINOX | |

| Nitro-V | 0.7% | 13.3% | x | 0.7% | x | x | 0.1% | 0.12% | x | 0.5% | x | ≤62 | USA / New Jersey Steel Baron | |

| 12C27M | 0.6% | 13.5% | x | 0.4% | x | x | x | x | x | 0.4% | x | ≤58 | sweden / Sandvik AB | |

| stainless steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| 12C27 | 0.6% | 13.5% | x | 0.4% | x | x | x | x | x | 0,40% | x | ≤58 | 33° 500x ; 30° 700x ; 24° 1000x | sweden / Sandvik AB |

| AEB-L (13C26; N611) | 0,68% | 13.00% | x | 0.65% | x | x | x | x | x | 0.40% | x | ≤59 | sweden / Sandvik AB | |

| 14C28N | 0.62% | 14.00% | x | 0.6% | x | x | x | 0.11% | x | 0.2% | x | ≤59 | 30° 925x | sweden / Sandvik AB |

| 19C27 | 0.95% | 13.5% | x | 0.65% | x | x | x | x | x | 0.4% | x | ≤62 | sweden / Sandvik AB | |

| AN-58 | 0.45% | 13.5% | 0.01% | 0.49% | x | x | 0.02% | x | x | 0.34% | x | ? | ||

| 420MoV (X50CrMoV15; 1.4116) | 0.55% | 15.00% | 0.8% | 1.00% | x | x | 0.2% | x | x | 1.00% | x | ≤55 | 30° 750x | germany / Krupp |

| Lam.Cos (Lam Cos) | 1.05% | 16.00% | 1.5% | x | 2.5% | 0.25% | x | x | 0.25% | x | x | ≤60 | 30° 1700x | |

| CTS-BD1 | 0.95% | 17.00% | 0.5% | 1.00% | x | x | 0.1% | x | x | 1.00% | x | ≤60 | USA / Carpenter Technology | |

| CTS-BD1N | 0.95% | 17.00% | 0.5% | 1.00% | x | x | x | 0.15% | x | 1.00% | x | ≤63 | USA / Carpenter Technology | |

| 95x18 | 1.00% | 19.00% | x | 0.8% | x | 0.6% | x | x | x | 0.8% | 0.2% Titanium (Ti) | ≤60 | russian / GOST | |

| Niolox (1.4153.03) | 0.8% | 12.7% | 1.1% | x | x | x | 0.9% | x | x | x | 0.7% | ≤60 | 30° 2200x | germany / Lohmann |

| stainless steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| VG1 | 1.00% | 14.00% | 0.3% | x | x | x | x | x | x | x | x | ≤60 | japan / Takefu special Steel | |

| VG2 | 0.65% | 14.00% | 0.15% | x | x | x | x | x | x | x | x | ≤59 | japan / Takefu special Steel | |

| VG5 | 0.75% | 14.00% | 0.3% | x | x | x | 0.15% | x | x | x | x | ≤59 | japan / Takefu special Steel | |

| VG7 | 1.00% | 14.00% | 0.3% | x | x | x | 0.15% | x | 1.25% | x | x | ≤61 | japan / Takefu special Steel | |

| VG10 (V-Kin-10) | 1.00% | 15.00% | 1.00% | x | 1.5% | x | 0.25% | x | x | x | x | ≤61 | japan / Takefu special Steel | |

| VG10W | 1.00% | 15.00% | 1.00% | x | 1.55% | x | 0.25% | x | 0.4% | x | x | ≤62 | japan / Myodo Metal Company | |

| H1 | 0.15% | 15.00% | 1.00% | 2.00% | x | 7.00% | x | 0.1% | x | 4.00% | x | ≤58 | ||

| H2 | 0.09% | 13.73% | 2.24% | 0.32% | x | 8.25% | x | 0.06% | x | 2.63% | 0.17% (Cu) | ≤58 | Japan / Myodo Metal Company |

Stainless steel made with powder metallurgy

| stainless steel - powder | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| 440XH (MicroMelt 440XH) | 1.6% | 16.00% | 0.8% | 0.5% | x | 0.35% | 0.45% | x | x | 0.4% | x | ≤60 | USA / Carpenter Technology | |

| CPM-154 | 1.05% | 14.00% | 4.00% | 0.5% | x | x | x | x | x | 0.3% | x | ≤61 | USA / Crucible Industries | |

| CPM-S30V | 1.45% | 14.00% | 2.00% | x | x | x | 4.00% | x | x | 0.5% | x | ≤61 | 36° 600x ; 30° 1500x ; 25° 3000x | USA / Crucible Industries |

| CPM-S35VN | 1.34% | 14.00% | 2.00% | 0.5% | x | x | 3.00% | x | x | 0.5% | 0.4% | ≤61 | 40° 1100x ; 30° 3100x | USA / Crucible Industries |

| CPM-S45VN | 1.48% | 16.00% | 2.00% | x | x | x | 3.00% | x | x | x | x | ≤61 | USA / Crucible Industries | |

| CPM-S60V | 2.15% | 17.00% | 0.4% | 0.4% | x | x | 5.5% | x | x | x | x | ≤60 | USA / Crucible Industries | |

| CPM-S90V | 2.3% | 14.00% | 1.00% | 0.5% | x | x | 9.00% | x | 0.4% | 0.5% | x | ≤59 | 30° 3000x | USA / Crucible Industries |

| CPM-S110V | 2.9% | 15.00% | 2.25% | 0.4% | 2.5% | x | 9.1% | x | x | 0.6% | 3.00% | ≤64 | 30° 2700x | USA / Crucible Industries |

| CPM-S125V | 3.3% | 14.00% | 2.5% | 0.5% | 2.5% | 0.2% | 11.85% | x | 0.4% | 0.9% | x | ≤64 | 30° 12400x ; | USA / Crucible Industries |

| RWL34 (RWL-34 PM; Z100CD14.4) | 1.05% | 14.00% | 4.00% | 0.5% | x | x | 0.2% | x | x | 0.5% | x | ≤64 | 36° 700x ; 30° 1160x ; 24° 3500x | sweden / DAMASTEEL |

| PMC27 (PMC-27) | 0.6% | 13.5% | x | 0.5% | x | x | x | x | x | x | 0.5% | ≤64 | sweden / DAMASTEEL | |

| CPM-20V | 1.9% | 20.00% | 1.00% | 0.3% | x | x | 4.00% | x | 0.6% | 0.3% | x | ≤62 | 40° 1100x ; 30° 2200x | USA / Latrobe -> Crucible Industries |

| CPM-SPY27 | 1.25% | 14.00% | 2.00% | 0.5% | 1.5% | x | 2.00% | 0.1% | x | 0.5% | 1% | ≤63 | USA / Crucible Industries | |

| stainless steel - powder | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| CTS-204P | 1.9% | 20.00% | 1.00% | 0.35% | x | x | 4.00% | x | 0.65% | 0.6% | x | ≤62 | USA / Carpenter Technology | |

| CTS-XHP | 1.6% | 16.00% | 0.8% | 0.5% | x | 0.35% | 0.45% | x | x | 0.4% | x | ≤64 | 30° 1550x | USA / Carpenter Technology |

| ELMAX SuperClean | 1.7% | 18.00% | 1.00% | 0.3% | x | x | 3.00% | x | x | 0.8% | x | ≤62 | 40° 1300x ; 37° 2700x ; 30°3400x | austria / Bohler Uddeholm |

| M390 MICRO CLEAN | 1.9% | 20.00% | 1.00% | 0.3% | x | x | 4.00% | x | 0.6% | 0.7% | x | ≤62 | 34° 1300x ; 30° 2700x ; 24° 3625x | austria / Bohler Uddeholm |

| M398 MICRO CLEAN | 2.7% | 20.00% | 1.00% | 0.5% | x | x | 7.2% | x | 0.7% | 0.5% | x | ≤66 | austria / Bohler Uddeholm | |

| Super Gold 2 | 1.45% | 16.00% | x | x | x | x | x | x | x | x | x | ≤62 | japan / Takefu special Steel | |

| ZDP189 (ZDP-189) | 3.00% | 20.00% | 1.4% | 0.1% | x | x | 0.1% | x | 1.5% | 0.4% | x | ≤67 | 30° 5200x ; 24° 6200x ; 20° 9400x | japan / Hitachi |

| Vanax (Vanax SuperClean) | 0.36% | 18.2% | 1.1% | 0.3% | 0.05% | 0.18% | 3.5% | 1.55% | 0.06% | 0.3% | x | ≤62 | 30° 2700x | austria / Bohler Uddeholm |

| Cowry-X | 3.00% | 20.00% | 1.7% | x | x | x | 0.9% | x | x | x | x | ≤65 | 30° 8250x | japan / Daido steel |

| LC200N (1.4108) | 0.3% | 15.00% | 0.95% | 1.00% | x | 0.5% | x | 0.5% | x | x | x | ≤61 | germany / Zapp Fine Grain | |

| SG2 (R2; SPGS) | 1.45% | 16.00% | 3.3% | 0.4% | x | x | 2.2% | x | x | 0.5% | x | ≤64 | japan / Kobelco Steel |

Tool steel

| tool steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| O1 ( Carpenter O1; 100MnCrW4; ČSN 19314; 1.2825; SKS3) | 0.9% | 0.5% | x | 1.2% | x | x | 0.2% | x | 0.5% | x | x | ≤65 | 30° 1350x | |

| O2 (AISI O2; 90MnCrV8; SKS93; ČSN 19312; 1.2842; K720) | 0.95% | 0.35% | 0.3% | 1.8% | x | 0.3% | x | x | x | 0.5% | 0.25% (Cu) | ≤64 | USA / Carpenter Technology | |

| A2 (X100CrMoV5 ;ČSN 19571PH; SKD12; 1.2363; K305) | 1.00% | 5.25% | 1.1% | 0.8% | x | x | 0.2% | x | x | 0.3% | x | ≤60 | ||

| A6 (70MnMoCr8; 1.2824; UHN1550) | 0.75% | 1.2% | 1.4% | 2.5% | x | x | x | x | x | 0.3% | x | ≤59 | USA / Carpenter Technology | |

| D2 (X155CrMoV121; ČSN 19573; SKD11; 1.2379; AIRDI 15, K110) | 1.6% | 11.5% | 0.9% | 0.45% | x | x | 1.1% | x | x | 0.4% | x | ≤62 | 40° 600x ; 30° 1400x | |

| S7 (50CrMoV13 ;ČSN 19550 ;1.2357) | 0.55% | 3.5% | 1.8% | 0.8% | x | x | 0.3% | x | x | 1.00% | 0.2% (Cu) | ≤61 | ||

| tool steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| T1 (X75WCrV18-4; SKH2; ČSN 19824; 1.3355) | 0.8% | 4.00% | x | 0.4% | x | 0.3% | 1.3% | x | 18.75% | 0.4% | 0.25% (Cu) | ≤65 | ||

| M1 (s1-8-1; SKH50; 1.3346) | 0.88% | 4.00% | 9.2% | 0.4% | x | 0.3% | 1.35% | x | 2.1% | 0.5% | 0.25% (Cu) | ≤65 | ||

| M2 (s6-5-2; ČSN 19830; SKH9; 1.3342) | 1.05% | 4.5% | 5.5% | 0.4% | x | 0.3% | 2.2% | x | 6.75% | 0.45% | x | ≤65 | ||

| M35 (s6-5-2-5; ČSN 19852; SKH55; 1.3243) | 0.95% | 4.5% | 5.25% | 0.4% | x | 0.4% | 2.15% | x | 6.75% | 0.4% | x | ≤65 | ||

| W1 (C100W1; ČSN 19133; SK3; 1.1645; K970) | 1.5% | 0.15% | 0.1% | 0.4% | x | 0.2% | 0.1% | x | 0.15% | 0.4% | 0.2% (Cu) | ≤66 | ||

| H13 (X40CrMoV51; ČSN19554; SKD61; 1.2344; W302) | 0.45% | 5.5% | 1.75% | 0.5% | x | 0.3% | 1.2% | x | x | 1.2% | x | ≤54 | ||

| tool steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| JIS SK3 | 1.1% | 0.3% | x | 0.5% | x | 0.25% | x | x | x | 0.35% | x | ≤61 | japan / Nisshin | |

| JIS SK4 | 1.00% | 0.3% | x | 0.5% | x | 0.25% | x | x | x | 0.35% | x | ≤60 | japan / Nisshin | |

| JIS SK5 | 0.9% | 0.3% | x | 0.5% | x | 0.25% | x | x | x | 0.25% | x | ≤60 |

carbon steel (high carbon content steel)

| carbon steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| 80CrV2; 19 419; W1.2235 | 0.85% | 0.6% | x | 0.5% | x | 0.4% | 0.25% | x | x | 0.4% | x | ≤61 | germany / Krupp | |

| Caldie | 0.7% | 5.00% | 2.3% | 0.5% | x | x | 0.5% | x | x | 0.2% | x | ≤62 | sweden / Bohler Uddeholm | |

| Sleipner | 0.9% | 7.8% | 2.5% | 0.5% | x | x | 0.5% | x | x | 0.9% | x | ≤64 | 35° 700x | sweden / Bohler Uddeholm |

| 1095 ( SUP4 ;1.1275 ) | 1.03% | x | x | 0.5% | x | x | x | x | x | x | x | ≤60 | ||

| 1095CroVan ( 1095CV ) | 1.14% | 0.6% | 0.06% | 0.5% | x | 0.25% | 0.25% | x | x | 0.25% | x | ≤60 | USA / Sharon Steel | |

| 52100 (100Cr6; ČSN14100; SUJ2; 1.3505) | 1.1% | 1.6% | x | 0.45% | x | 0.3% | x | x | x | 0.3% | x | ≤59 | ||

| 1084 (1.0616) | 0.93% | x | x | 0.9% | x | x | x | x | x | x | x | ≤59 | ||

| 1080 (AISI 1080; 80Mn4; 1.1259; 75A) | 0.88% | x | x | 0.9% | x | x | x | x | x | x | x | ≤58 | ||

| 1075 (1.1248) | 0.8% | x | x | 0.7% | x | x | x | x | x | x | x | ≤55 | ||

| 1060 (AISI 1060; C60;1.0601; 60) | 0.65% | x | x | 0.9% | x | x | x | x | x | x | x | ≤57 | ||

| carbon steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| 1065 (AISI 1065; XC65; 1.1230) | 0.7% | x | x | 0.9% | x | x | x | x | x | x | x | ≤57 | ||

| 1045 (ČSN19083; 1.1191) | 0.5% | x | x | 0.9% | x | x | x | x | x | x | x | ≤52 | ||

| 5160 (60Cr3; 1.7177) | 0.64% | 0.9% | x | 1.00% | x | x | x | x | x | 0.3 | x | ≤60 | ||

| 65Mn (AISI 1066) | 0.71% | 0.25% | x | 1.1% | x | x | x | x | x | 0.37 | x | ≤58 | ||

| CruForgeV (1086V) | 1.05% | 0.5% | x | 0.75% | x | x | x | x | x | x | x | ≤64 | USA / Crucible Industries | |

| Y7XR | 0.8% | 5.00% | 5.00% | x | x | x | x | x | x | x | x | ≤66 | japan / Hitachi | |

| V-Toku1 (Takefu V1 Special) | 1.15% | 0.35% | x | x | x | x | 0.2% | x | 2.25% | x | x | ≤64 | japan / Takefu special Steel | |

| V-Toku2 (Takefu V2 Special) | 1.05% | 0.5% | x | 0.5% | x | 0.25% | 0.2% | x | 1.25% | 0.35% | x | ≤62 | japan / Takefu special Steel | |

| Shiro2 (Takefu Shiro 2) | 1.00% | 0.3% | x | x | x | 1.00% | x | x | x | x | x | ≤64 | japan / Takefu special Steel | |

| V-Gin1 (Stainless Chromax; V1 Silver) | 1.00% | 5.00% | 1.00% | 0.9% | x | 0.25% | 0.5% | x | x | 0.4% | x | ≤61 | japan / Takefu special Steel | |

| carbon steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| Gin2 (Stainless Chromax) | 0.9% | 7.5% | x | x | x | x | x | x | x | x | x | ≤62 | japan / Takefu special Steel | |

| V-Gin3B (Stainless Chromax) | 0.85% | 6.5% | 0.8% | x | x | 0.5% | 0.4% | x | 0.5% | x | x | ≤62 | japan / Takefu special Steel | |

| 8670 (AISI 8670; 1.2703) | 0.75% | 0.5% | 0.15% | 0.6% | x | 1.00% | x | x | x | 0.35% | x | ≤61 | ||

| Yellow steel (Kigami #2) | 1.15% | x | x | 0.3% | x | x | x | x | x | 0.2% | x | ≤61 | japan / Hitachi (Yasugi) | |

| Yellow steel (Kigami #3) | 0.9% | x | x | 0.3% | x | x | x | x | x | 0.2% | x | 60 | japan / Hitachi (Yasugi) | |

| WhiteSteel #2 (Shirogami #2) | 1.15% | x | x | 0.3% | x | x | x | x | x | 0.2% | x | ≤61 | japan / Hitachi (Yasugi) | |

| WhiteSteel #1 (Shiroogami #1) | 1.35% | x | x | 0.3% | x | x | x | x | x | 0.2% | x | ≤62 | japan / Hitachi (Yasugi) | |

| Blue steel #2 (Aogami#2, Ao-ni ko) | 1.15% | 0.5% | x | 0.3% | x | x | x | x | 1.5% | 0.2% | x | ≤63 | japan / Hitachi (Yasugi) | |

| Blue steel #1 (Aogami #1, Ao-ichi ko) | 1.35% | 0.5% | x | 0.3% | x | x | x | x | 2.00% | 0.2% | x | ≤65 | japan / Hitachi (Yasugi) | |

| BlueSuper steel (Super Blue, Aogami super) | 1.5% | 0.5% | x | 0.3% | x | x | 0.5% | x | 2.5% | 0.2% | x | ≤66 | japan / Hitachi (Yasugi) | |

| S600 (Bohler S600; 1.3343) | 0.9% | 4.1% | 5% | x | x | x | 1.8% | x | 6.2% | x | x | ≤64 | Sweden / Bohler Uddeholm |

carbon steel (high carbon content steel) made with powder metallurgy

| powder carbon steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer | |

| CPM REX M4 ( CPM-M4; M4; SKH54; 1.3394) | 1.42% | 4.00% | 5.25% | 0.3% | x | x | 4.00% | x | 5.5% | 0.55% | x | ≤65 | 30° 2300x | USA / Carpenter Technology |

| Maxamet ( Micro-Melt Maxamet) | 2.15% | x | x | 0.3% | 10.00% | x | 6.00% | x | 13% | 0.25% | x | ≤69 | USA / Carpenter Technology | |

| CPM-3V | 0.8% | 7.5% | 1.3% | 0.4% | x | x | 3.00% | x | 0.4% | 0.9% | x | ≤64 | USA / Crucible Industries | |

| CPM-15V | 3.4% | 5.25% | 1.3% | 0.5% | x | x | 14.9% | x | 0.4% | 0.9% | x | ≤63 | 42° 950x ; 30° 10600x | USA / Crucible Industries |

| CPM-MagnaCut | 1.15% | 10.7% | 2.00% | 0.5% | x | x | 4.00% | 0.2% | x | 0.4% | 2.00% | ≤65 | USA / Crucible Industries | |

| CPM CruWear (CRU-WEAR; CruWear; 1.2895) | 1.1% | 7.25% | 1.6% | x | x | x | 2.4% | x | 1.15% | 1.2% | x | ≤65 | USA / Crucible Industries | |

| K390 | 2.47% | 4.2% | 3.8% | 0.4% | 2.00% | x | 9.00% | x | 1% | 0.55% | x | ≤64 | sweden / Bohler Uddeholm | |

| K490 | 1.4% | 6.4% | 1.5% | x | x | x | 3.7% | x | 3.5% | x | ? | ≤65 | sweden / Bohler Uddeholm | |

| CPM REX45 | 1.3% | 4.05% | 5.00% | 0.3% | 8.00% | x | 3.05% | x | 6.25% | 0.5% | x | ≤66 | USA / Crucible Industries | |

| CPM REX76 | 1.5% | 3.75% | 5.25% | 0.3% | 8.5% | x | 3.1% | x | 9.75% | 0.3% | x | ≤67 | USA / Crucible Industries | |

| powder carbon steel | (C) | (Cr) | (Mo) | (Mn) | (Co) | (Ni) | (V) | (N) | (W) | (Si) | (Nb) | HRc | verified ideal grinding angle (number of cuts on 20mm rope - Pavol Sandor test) | manufacturer |

| CPM REX121 | 3.4% | 4.00% | 5.00% | x | 9.00% | x | 9.5% | x | 10.00% | x | x | ≤71 | 36° 3950x ; 30° 6200x | USA / Crucible Industries |

| Z-Max | 2.00% | 4.00% | 5.00% | x | 9.00% | x | 5.00% | x | 10.00% | 0.12% | x | ≤68 | germany / ZAPP | |

| Vanadis8 | 2.3% | 4.8% | 3.6% | 0.4% | x | x | 8.00% | x | x | 0.4% | x | ≤65 | 36° 945x ; 30° 7800x | sweden / Bohler Uddeholm |

| K294 microclean | 2.45% | 5.2% | 1.3% | 0.5% | x | x | 9.7% | x | x | 0.9% | x | ≤63 | sweden / Bohler Uddeholm | |

| K190 microclean | 2.3% | 12.5% | 1.1% | 0.3% | x | x | 4% | x | x | 0.6% | x | ≤65 | sweden / Bohler Uddeholm |

or

or  it will show the search option on the page and enter the steel you are looking for in this field.

it will show the search option on the page and enter the steel you are looking for in this field.